American has two solutions to this problem depending on severity.

Solution 1

Exterior Excavation Method is used when wall bulging or wall tipped inwards over 1 inch

- Major items covered with plastic and carpet runners.

- Cover grass with plywood sheathing to protect repair area.

- Excavate foundation to the footing.

- Haul away clay, set hydraulic jacks, remove loose back-plaster.

- Chip out mortar joints as necessary for straightening.

- Straighten walls back to original position.

- Rebuild block walls that are severely bulged

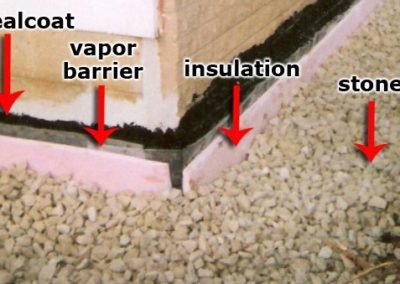

Re-waterproof Exterior with 4-Step Process

- Back-plaster cement from footing to grade line.

- Seal coat of waterproofing hydro-shield mastic over back-plaster.

- Cover back-plaster and seal-coat with vapor barrier plastic.

- Insulation to be installed on walls for expansion control.

- Flush out bleeders and inside drain tile to sump pump or sewer.

- Install new exterior drain tile and connect to existing system at trench.

- Cover new drain tile with engineered lightweight non-expandable stone to one foot from the top surface per WAFRP standards.

- Cover drain tile and stone back-fill with filter fabric.

- Install custom engineered steel structures at intervals of Approx. 32″ on center.

- Reinforce walls with concrete piers and steel rods in cells of block if needed.

- Re-mortar broken block and mortar joints (tuck-point) inside and outside.

- Compact topsoil with proper pitch at area excavated.

- Reinstall window wells with 100% stone to footing.

- Clean job site at repair area and remove all debris as requested.

- City permits may be required and will be included upon request.

Licensed, Bonded and Insured! We’ve been in business for 70 years and all our work backed by our 20 year warranty! Warranty has no yearly renewal fees and is transferable to new owners.

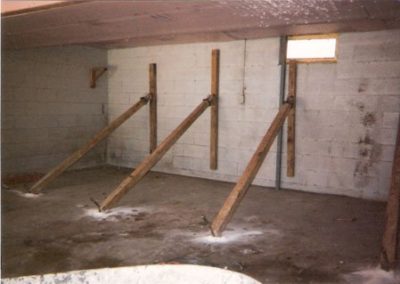

Solution 2

Engineered Steel Method used when wall bulging or tipped inwards under 1 inch

- Engineered steel structures are anchored professionally to the concrete floor and footing along the bottom, and skillfully attached to the upper floor joists or to the added joist supports on non-bearing walls for additional strength.

- Engineered steel structures are grouted in with hydraulic cement for future expansion or contraction.

- Engineered steel structures are anchored approximately 32″ on center, depending on engineer’s report.

- All broken block and mortar joints are re-mortared or tuck-pointed.

- All engineered steel structures are guaranteed per proposal or up to 20 years.

- City permits may be required and will be included upon request.

Licensed, Bonded and Insured! We’ve been in business for 75 years and all our work backed by our 20 year warranty! Warranty has no yearly renewal fees and is transferable to new owners.